Travertine Tech

More Value from

Every Ore

Next Gen Phosphate Technology

TRAVERTINE PRODUCTS

Purified Phosphoric Acid

TRAVERTINE PRODUCTS

Sulfuric Acid

TRAVERTINE PRODUCTS

Cementitious Materials

TRAVERTINE PRODUCTS

Carbon Dioxide Removal Credits

TRAVERTINE PRODUCTS

Extracting More Value

Phosphorus for the 21st century

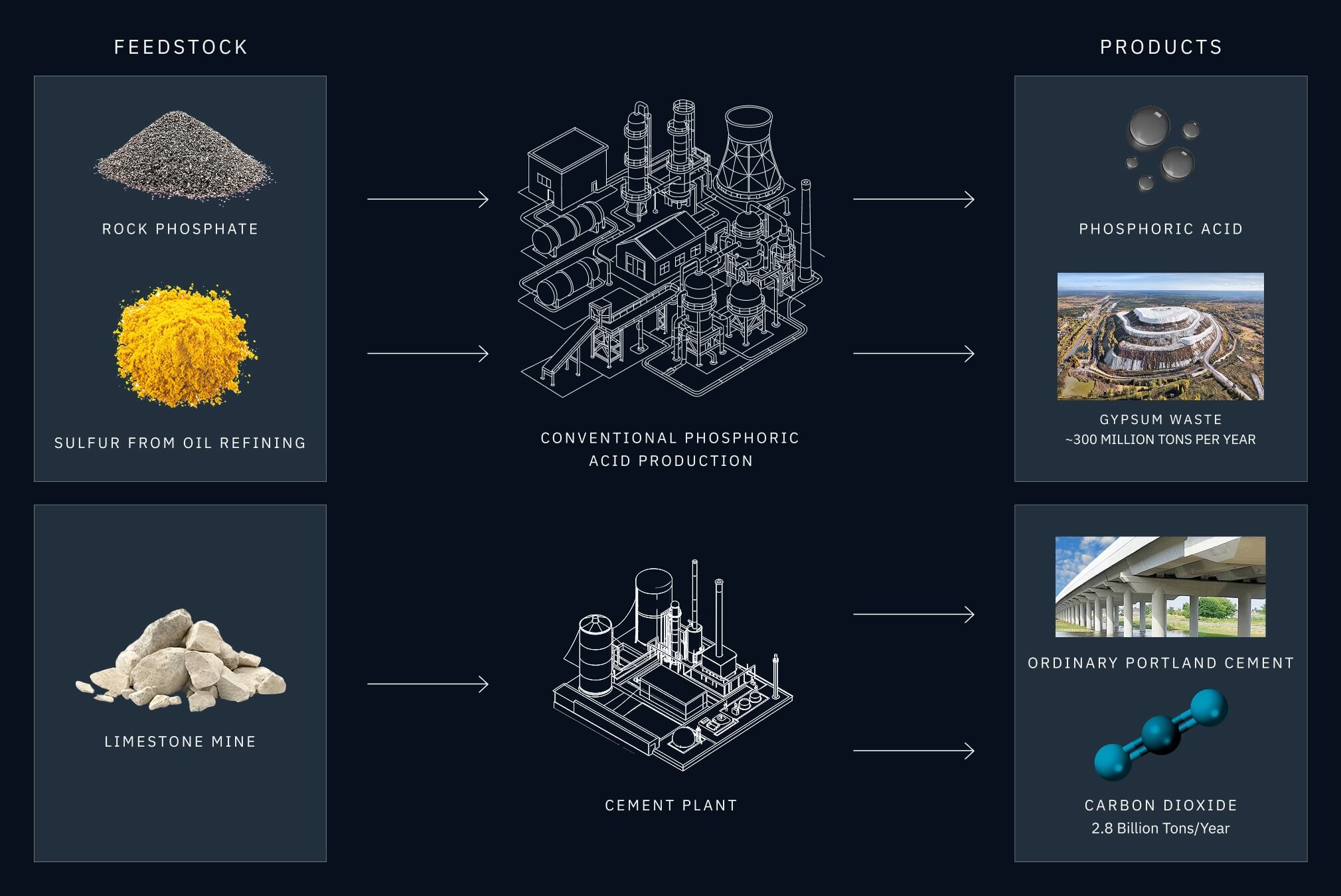

Legacy phosphate technology was developed more than a century ago. Today, land and resources are scarce and byproduct management is costly. Travertine’s next-generation phosphate technology is circular, carbon-negative, and extracts more value from the same ore. We are here to meet the vital material needs of today while helping preserve a brighter tomorrow.

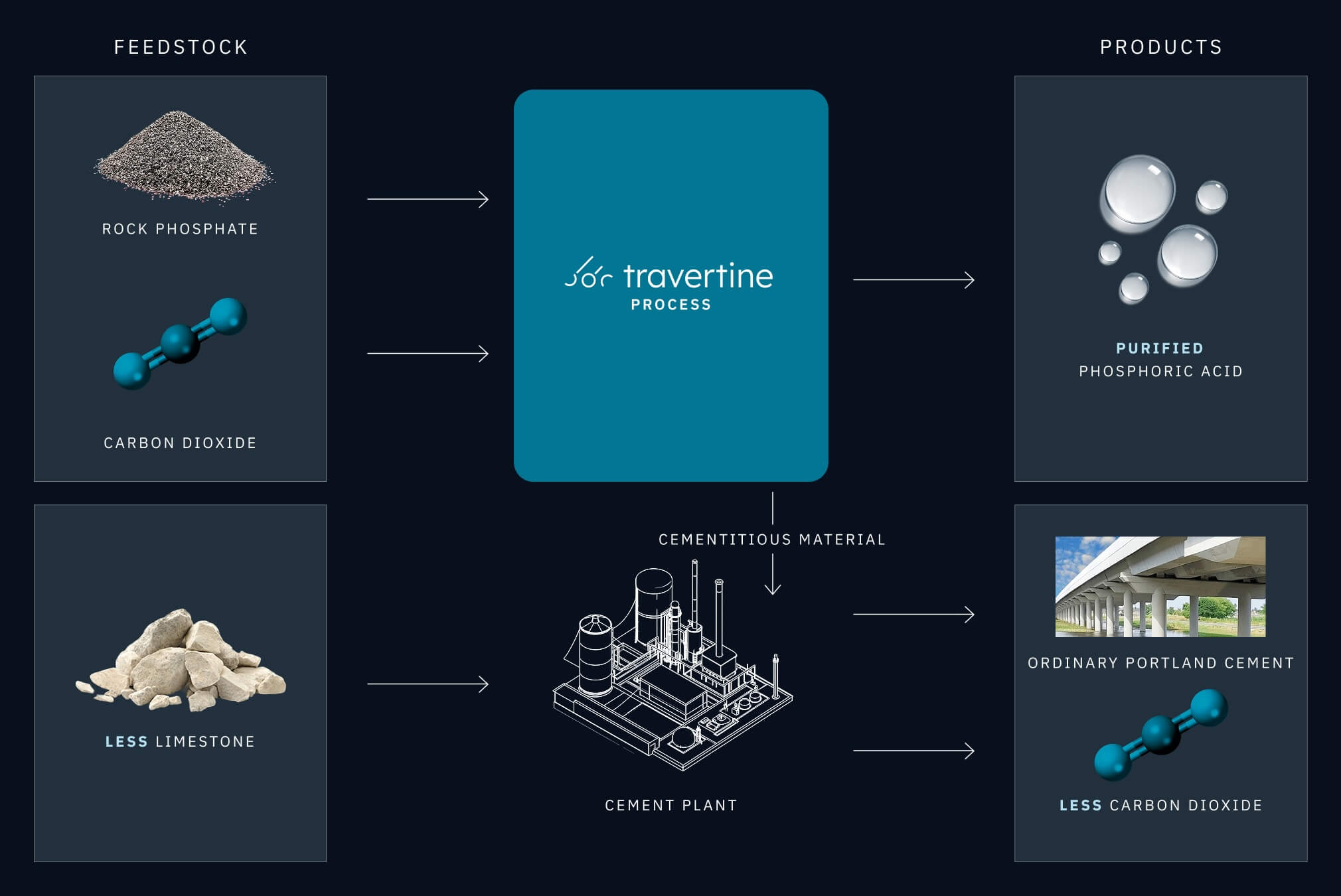

Travertine’s breakthrough technology produces phosphoric acid and cementitious materials instead of byproducts that are landfilled.

Closing the Loop between fertilizer and cement Industries

Use up and down arrow keys to move between tabs.

Travertine technology by the numbers

-

Gypsum waste avoided

>98%

Conversion efficiency gypsum to calcium carbonate

-

Ore concentrate utilized

100%

VS ~50% PHOSPHATE industry standard

-

Carbon dioxide mineralized

0.75 T

Per Ton of Phosphoric Acid

Avoid sulfur costs, sulfates landfill, extract more value, lower cost, remove carbon.

Avoid sulfur costs, sulfates landfill, extract more value, lower cost, remove carbon.

Avoid sulfur costs, sulfates landfill, extract more value, lower cost, remove carbon.

Avoid sulfur costs, sulfates landfill, extract more value, lower cost, remove carbon.

Avoid sulfur costs, sulfates landfill, extract more value, lower cost, remove carbon.

Avoid sulfur costs, sulfates landfill, extract more value, lower cost, remove carbon.

Avoid sulfur costs, sulfates landfill, extract more value, lower cost, remove carbon.

ELECTRIFIED CHEMICAL INDUSTRY

Travertine was built to extract more value from ore while solving massive environmental challenges. We are scaling in partnership with the world’s largest industries: mining, cement, fertilizer.