Demonstration Plant Project

Demonstration Plant

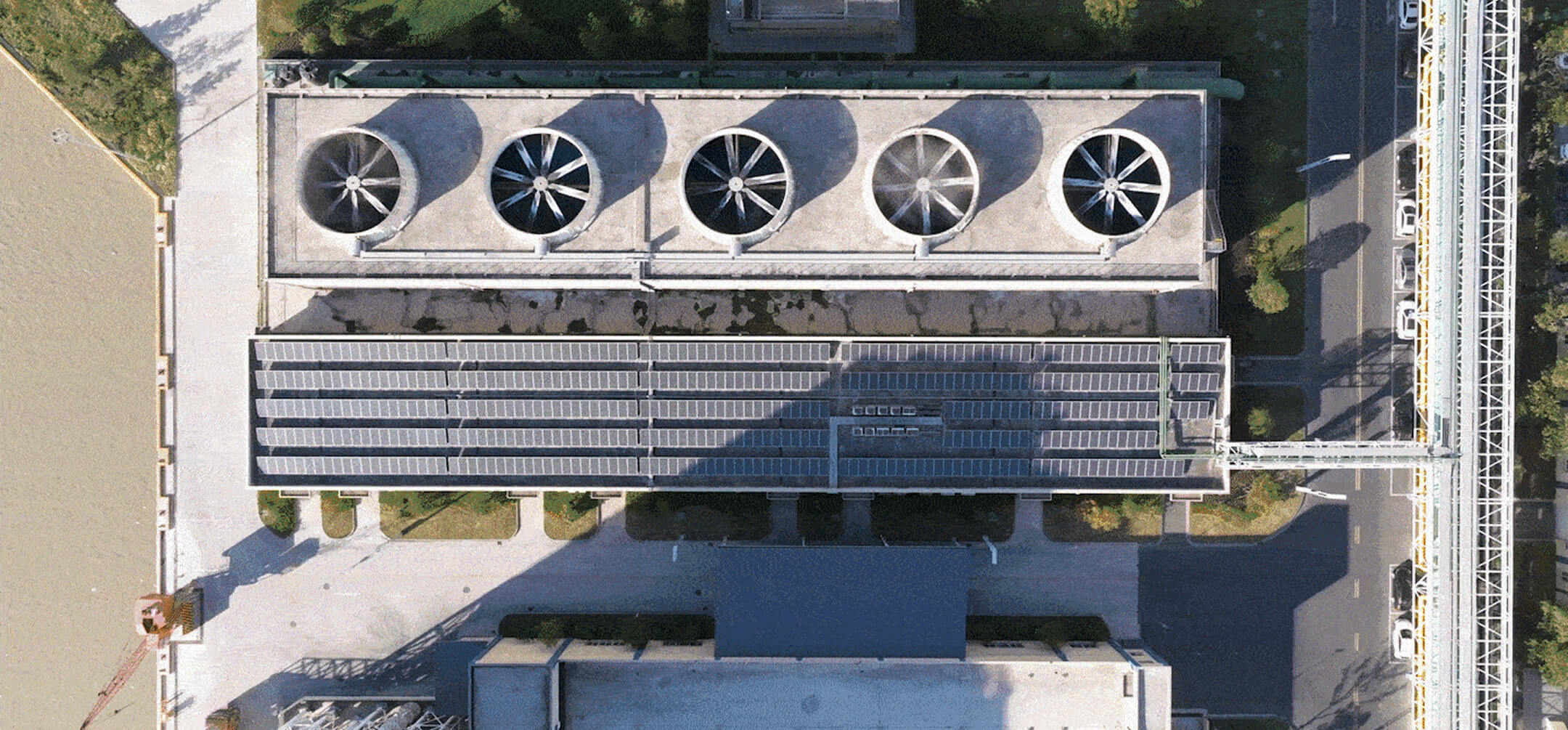

Ontario, New York, USA

Travertine Products

Purified Phosphoric Acid

Travertine Products

Cement Materials

Travertine Products

Carbon Dioxide Removal

Travertine Products

Extracting More Value

Travertine Products

Sulfuric Acid

A first-of-a-kind demonstration

Successful demonstration of new technology using commercial-scale equipment is a critical step in bringing innovations out of the lab into the real world.

Travertine’s Demo facility is designed to showcase the Travertine Core Process, which combines salt-splitting electrolysis, direct air capture (DAC), and mineralization. The process converts gypsum (calcium sulfate) and carbon dioxide from the air into sulfuric acid and calcium carbonate. Green hydrogen is an additional product we can choose to make. Data from the Demo Plant will be used to optimize engineering for commercial plants.

In line with our no-waste ethos, products of our Demo Plant will be used by local partners, including a precious metal recycler and a cement producer. At scale, the sulfuric acid produced by Travertine’s Core Process will be used to extract phosphoric acid from phosphate rock for the fertilizer and battery industries.

This Demonstration Plant was started up in October 2025. The project was completed on time and on budget, a significant achievement for a first-of-a-kind plant.

Project Metrics

-

Carbon dioxide sequestration

56T

per year, gross mineralization

-

Sulfuric acid production

125T

Per year, 100% basis

-

Electrolyzer stack cell area

8m2

Ribbon Cutting Ceremony

Travertine brought together the local community and partners that supported us in building this first-of-a-kind facility for a ribbon cutting ceremony on October 2nd, 2025. This project was enabled by a grant from NYSERDA, funding from Builders Vision, and a prepurchase from Frontier. Project partners include the Town of Ontario, Sabin Metal Corporation, Zeton, Inc., Industrie De Nora S.p.A., Nichols Construction Team, and many others.

Installation

This plant was installed in the summer, commissioned in September, and started operation in October 2025.

Operation

Operations started in October 2025 and the plant is in continuous operation producing on-specification sulfuric acid and calcium carbonate products.